Vertical Slurry Pumps and their spare parts are interchangeable with pumps. They are designed to transport corrosive, coarse particles and high-concentration slurries. It can operate normally without shaft gland or shaft gland with water, and the shaft length can be customized according to the liquid level depth.

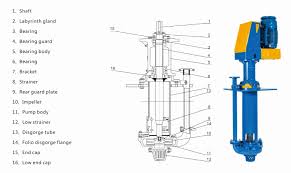

The pump is a vertical centrifugal slurry pump. The inlet is vertically downward on one side of the pump, and the outlet is vertically upward on the other side. It consists of a lower filter platform, pump body, impeller, shaft, guard plate and bracket. The upper part of the pump is supported by bearings; the pump is installed under the liquid and does not use a shaft seal. It adopts belt drive (BD) and direct drive (CD) transmission modes. The immersion depth within the standard size range can be adjusted according to user needs.

Vertical Slurry Pump is a highly configurable pumping equipment designed to reduce maintenance and operating costs. Compared with horizontal pumps, they require less floor space, and wear-resistant parts can be made of hard metal or rubber.

Series KTS sump pumps are vertical, centrifugal slurry pumps submerged in water to work. They are designed for delivering abrasive, large particle and high-density slurries. These Pumps needn’t shaft sealing or sealing water. They also can be operated normally for insufficient suction duties.

1. Vertical, submerged, cantilever shaft sewage slurry pump

2. Fully cantilevered

3. Shell

The metal Vertical Slurry Pump has a thick-walled, wear-resistant 27% chromium alloy shell. The rubber pump has a molded rubber casing that is adhered to a solid metal structure.4. Bearing assembly

The ratio of bearing, shaft and bearing housing is large to avoid problems related to the operation of the cantilever shaft in the first critical speed zone. The easy-to-maintain bearing assembly has heavy-duty roller bearings, a sturdy bearing seat, and a thick shaft.5. Column assembly

Made entirely of wear-resistant carbon steel. The model is rubber covered.6. Axis

Different lengths of pump drive shaft or suction extension pipe can be selected7. Casing

There is a simple bolt fixedly attached to the bottom of the column. The pump series are made of wear-resistant alloy, and the pump series are made of molded rubber.

8. Impeller

Double-suction semi-open impeller design, wear-resistant alloy, polyurethane and molded elastomer impellers are interchangeable. Large-particle impellers are also provided, which can pass unusually large solids. Unique double-suction impeller; fluid flow enters the top and bottom. This design eliminates the shaft seal and reduces the thrust load on the bearing. The gap between the impeller and the guard can be adjusted to ensure the efficient operation of the Vertical Slurry Pump.9.Upper Strainer

Embedded metal mesh; snap-on elastomer or polyurethane for Vertical Slurry Pump. The filter fits the column opening. A snap-in elastic filter is installed in the column opening to prevent excessive particles and unwanted garbage from entering the pump housing.10.Lower Strainer

Bolt metal or polyurethane for pumps; molded snap-on elastomer for pumps. The bolted connection cast filter on the metal pump and the molded snap-on elastomer filter on the rubber pump protect the pump from excessive particles.11. Drain pipe

Vertical Slurry Pump uses metal; rubber covers Vertical Slurry Pump. All wetted metal parts are completely rust-proof, the metal pump column and discharge pipe are made of steel, and the rubber column and discharge pipe are covered with rubber.12. Stirrer

Keep the solid in suspension, or install a mechanical agitator on an extension shaft protruding from the eye of the impeller.13. The vertical slurry pump does not require any sealing and sealing water.

Vertical Slurry Pump is widely used in mineral processing, mining and beneficiation, conveying concentrate, tailings, sand, metallurgy, copper, iron ore, diamond, alumina industry, coal, gold, kaolin, gravel and sand, chemical processing, Chemical slurry, sewage treatment, grinder, ash treatment, coarse sand, lime mud, phosphoric acid, sump dredging, mill grinding, pit pumping, oxide scale pumping, pulp and papermaking, desulfurization, sand mixing, construction , Tunnel boring, power plant, potash fertilizer plant, pumping machine cutting chips, sawdust suction, aerated mud and other industries.

If you need to know more about other mud pump products, please click here!

If you have any questions or need help, you are welcome to consult us at any time!

Name: KATImachinery

Mobile:+86031180632344

Tel:+86031180632344

Email:info@katimachinery.com

Add:306-1 Zhongchuang building 5,No.251 Yucai street, Shijiazhuang China