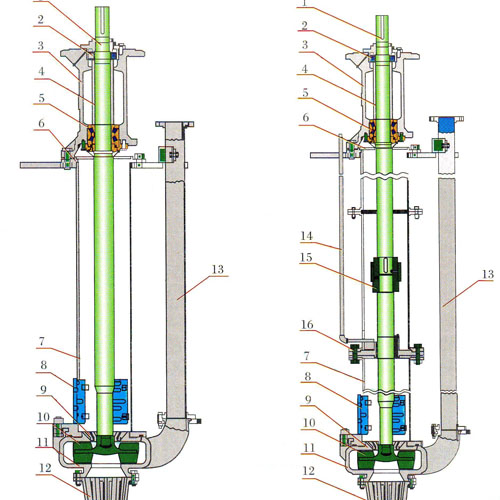

Sump pump is a vertical, centrifugal pump. It is suitable for delivering abrasive or corrosive slurry and the pump is always immersed in the liquid or pit to operate. There are two kinds of sump pumps, A05 material type and rubber type, but they have the same construction. The wet parts and shaft for A05 sump pump is made of wear-resistant metal for delivering abrasive slurry. The rubber sump pump is lined with corrosive-resistant rubber for delivering corrosive slurry. Both of these 2 type sump pumps are widely used for mining, chemical industry and so on. These pumps have no need of any shaft seal and sealing water. The type with “L” is a sump pump of extended shaft series, which is suited for the working condition of deeper level. The guide bearing construction is added to the pump on the basis of the standard pump, so the pump is with both more steady operation and wider application range, but flushing water should be attached to the guide bearing.

What is the construe of sump pump ?

Sump pump is vertical and centrifugal slurry pump. The pump casing, impeller and wear plate are made of wear-resistant material. The pump casing is fixed on the frame with bolts and the bearing body is installed on the top end of the frame. The double rows taper roller bearing near pump and the single row cylindrical roller bearings near drive end may stand the max. axial load of the pump. The base plate or frame of motor is installed on the bearing body. They may be directly driven or by V-belt. The belt pulley may be easily replaced for adjusting the pump speed to meet the duty variation or performance variation after the pump is worn. There are split mounting plates on the frame. The mounting plates may be easily mounted on the steel frame base of concrete base. It has the advantages of easy installation and convenient operation. Pump can be immersed in the slurry sump for work. The inlet of pump is equipped with lower strainer so as to prevent the large particles from entering the pump.

The construction of Rubber sump pump is the same to A05 sump pump perfectly, but for rubber sump pump, the outside of parts immersed in the slurry is lined with corrosive-resistant rubber. These parts with rubber liners are pump casing, impeller and wear plates. The connecting bolts immersed in the liquid are all lined with rubber protecting bush. The driving end of rubber sump pump is as same as A05 sump pump.

Part 1

How to assembly the bearing of sump pump?

When assembly, the bearing assemblies must be preheated and the temperature must not be more than 120℃. Double-row taper roller bearings are adopted for the lower bearing and their cone, cup and position sleeve is assembled in set, which can not be interchangeable with corresponding parts of the same kind of bearings. When the lower end cover of bearing is assembled, it must be noted that the surface of lip seal in recess of lower end cover should be outward and the oil retainer, etc. must agree to the position in assembly drawing. When piston ring is assembled, it must be noted that the mouth of th piston ring should not be overlapped at the direction of diameter. Because axial clearance has been ensured by bearings themselves, the clearance of the bearing assembly of the sump pump should not be adjusted in the assembly.

Part 2

Installation of Support, Mounting Plates and Pump Casing of sump pump

The bearing assembly and support is connected by bolts. The split mounting plates are assembled around the circle of support and fixed on support with studs. Then back liner, impeller and pump casing is assembled. When assembling, it must be noted that the relative position among bearing body, support, mounting plates and pump casing must be corresponding to the following figure to ensure the relative position of discharge pipe and oil nozzle.

The guide bearing section and upper frame are added with the Extended A05 sump pump and rubber sump pump, it should be noticed that:

A. The guide bearing should be installed between the upper frame and the frame;

B. Shaft Sleeve is hot-installed on the shaft, and machined along with the shaft, so it can not be disassembled.

C. The shaft bush of the metal pump is fixed on the bearing base with the bolts. The shaft bush of the rubber pump is stick at the bearing base with the glue.

D. Notice the relative positions of the each parts when assembly.

The connection bolts between support and pump casing must be smoothly locked. Check if the impeller rotates stably (if there is friction, put an insert at connecting bolts between bearing body and support to adjust it.). At last, the upper & lower strainer and discharge is installed, the upper part of discharge is fixed on the mounting plate by screws.

Before starting the pump unit should be checked according to the following processes:

1) The pump should be installed on the compact foundation so as to bear all of the pump weight to remove vibration. All of the foundation bolts should be locked.

2) When V-belt drive, the pump shaft should be parallel with the motor shaft. When direct drive, the pump shaft should be concentrically with the motor shaft, otherwise vibration will be occurred to cause the coupling and bearing exactly worn and V-belt excessively worn.

3) The pipeline and valves should be concentrically with flanges and single support is adopted.

4) When the shaft is rotated in clockwise by hand, the shaft should rotates freely.

5) When the coupling or V-Belt is installed well, the rotation of the mtor should be checked. The rotation direction of motor should agree with the arrow direction shown on the pump, otherwise the impeller may be fallen off from the shaft to cause serious accident.

6) At last check again whether all nuts are locked and the shaft rotates freely. The pump should be started with clean water before pumping slurry.

We are sump pump manufacturer. If you are interested in our products, please feel free to contact us.

Name: KATImachinery

Mobile:+86031180632344

Tel:+86031180632344

Email:info@katimachinery.com

Add:306-1 Zhongchuang building 5,No.251 Yucai street, Shijiazhuang China